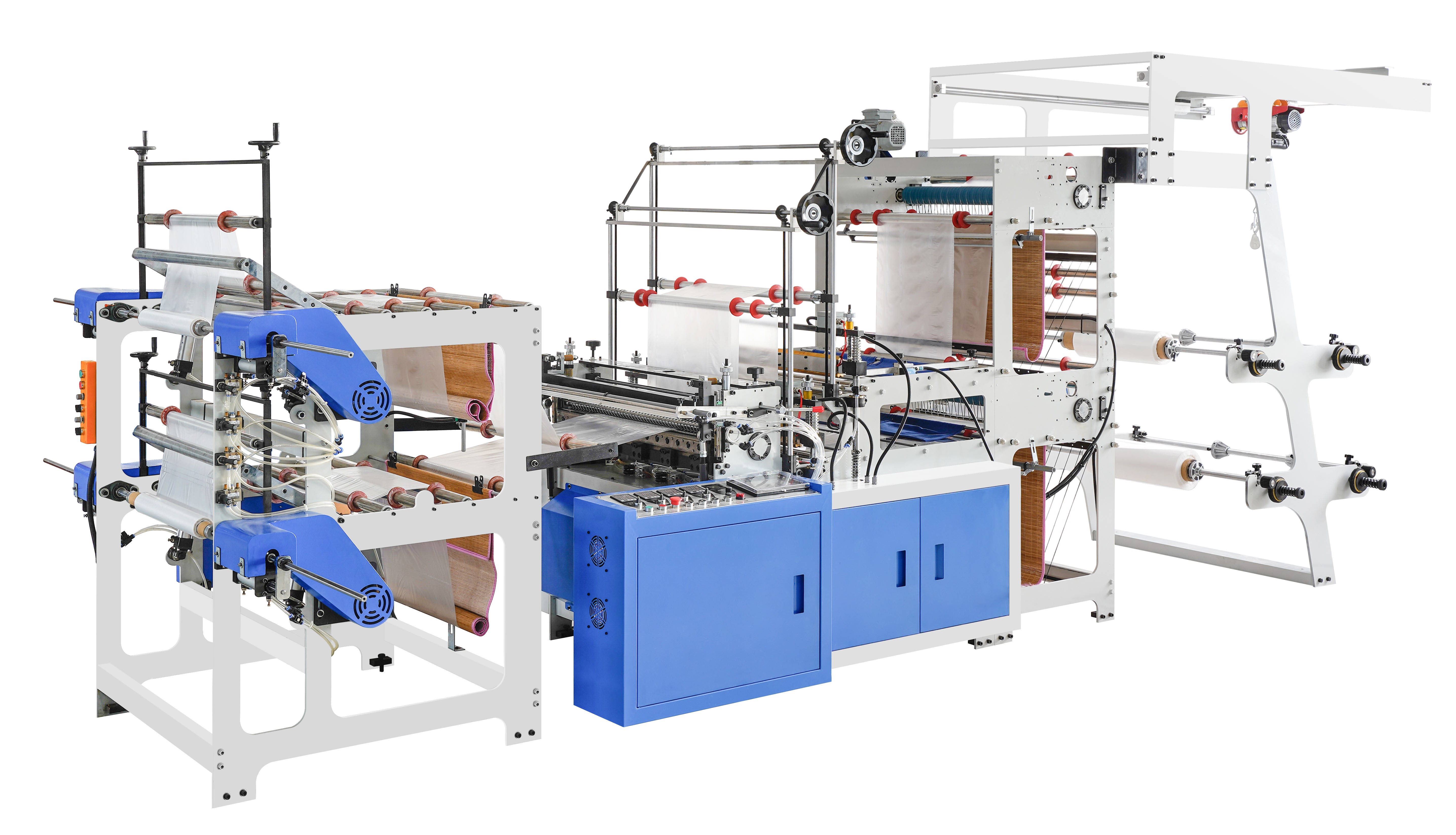

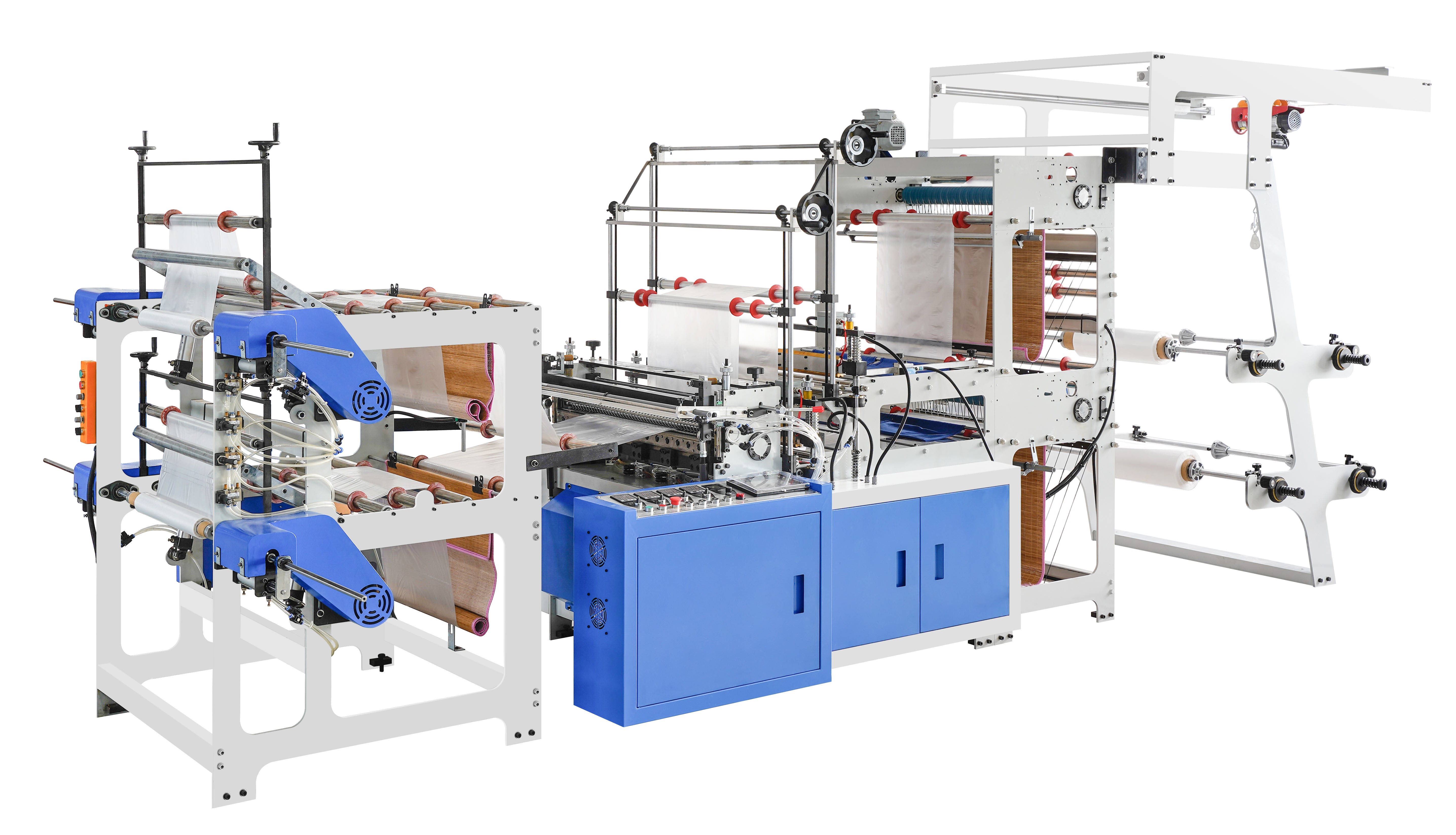

Product Overview

Our T-shirt Bags On Rolls Making Machine With Puncher is a high-efficiency and multi-functional equipment designed for producing roll-type T-shirt bags and flat opening bags. It integrates advanced cold cutting technology and precise punching functions, meeting the diverse packaging needs of both civil and industrial fields. The machine is equipped with a 2 Layers 4 Lines Cold Cutting system, which ensures clean and smooth bag sealing edges without burrs. This feature greatly improves the product qualification rate and reduces material waste. Whether you need small-sized bags for daily necessities or large-sized bags for clothing packaging, this machine can be flexibly adjusted to meet your production requirements. Its compact structure and easy operation make it an ideal choice for small and medium-sized enterprises that pursue cost-effectiveness and production efficiency.

Key Performance & Characteristics

High-efficiency Multi-line Production

The 2 Layers 4 Lines Cold Cutting design enables the machine to produce 4 lines of bags simultaneously, doubling the production efficiency compared with single-line or double-line equipment.

The cold cutting technology avoids thermal damage to the plastic film, ensuring the strength and durability of the bag sealing parts.

Precise Punching Function

The built-in puncher is highly precise, which can create uniform and neat hanging holes on T-shirt bags. The hole position is adjustable to adapt to different bag sizes and design requirements.

The punching device is wear-resistant and has a long service life, reducing the frequency of parts replacement and maintenance costs.

Flexible Bag Type Compatibility

This machine supports the production of both T-shirt bags on rolls and flat opening bags, realizing the dual-purpose of one machine. It can quickly switch between different bag types by simple parameter adjustment.

It is compatible with various common plastic film materials, such as low density polyethylene (LDPE) and high density polyethylene (HDPE), expanding the scope of application.

Technical Specifications

Parameter | Details |

Production Line Configuration | 2 Layers 4 Lines |

Cutting Method | Cold Cutting |

Applicable Bag Types | T-shirt bags on rolls, flat opening bags |

Punching Function | Built-in, adjustable hole position |

Applicable Materials | LDPE, HDPE plastic film |

Operation Mode | Semi-automatic (manual parameter setting + automatic production) |

Main Advantage | Dual-purpose, low material waste |

Application Scenarios

Daily Necessities Retail Industry

Supermarkets, convenience stores and grocery stores can use this machine to produce roll-type T-shirt bags. These bags are easy to take and use, which is convenient for customers to pack daily necessities such as snacks, toiletries and stationery.

Clothing and Textile Industry

The machine can produce large-sized flat opening bags or T-shirt bags with punching functions for packaging clothes, scarves and other textiles. The neat punching design is convenient for hanging and displaying the packaged products.

Small-scale Packaging Enterprises

For small and medium-sized packaging factories with limited site area and budget, this multi-functional machine can meet the customized production needs of different customers, improving the market competitiveness of enterprises.

FAQ

What is the difference between cold cutting and hot cutting technology?

Cold cutting uses sharp blades to cut plastic film at room temperature, which will not cause thermal deformation of the film. The sealing edge of the produced bag is smooth and firm. Hot cutting uses heat to melt and cut the film, which is easy to produce burrs and damage the film structure.

Can this machine adjust the size of the produced bags?

Yes, the machine can flexibly adjust the width and length of the bags according to your needs. You only need to modify the corresponding parameters on the operation panel to complete the adjustment quickly.

Is the punching device easy to maintain?

The punching device is made of high-hardness alloy materials, which is wear-resistant and corrosion-resistant. Regular cleaning and lubrication can ensure its long-term stable operation. We will provide detailed maintenance instructions when delivering the machine.

Call to Action

Are you looking for a cost-effective and multi-functional bag making machine to expand your production business? Our T-shirt Bags On Rolls Making Machine With Puncher is your best choice! Contact us now to inquire about the latest price and detailed technical parameters. We can also provide customized solutions according to your specific production needs. Don’t miss this opportunity to improve production efficiency and reduce costs. Click the "Inquire" button or send us an email, and our professional team will reply to you within 24 hours!