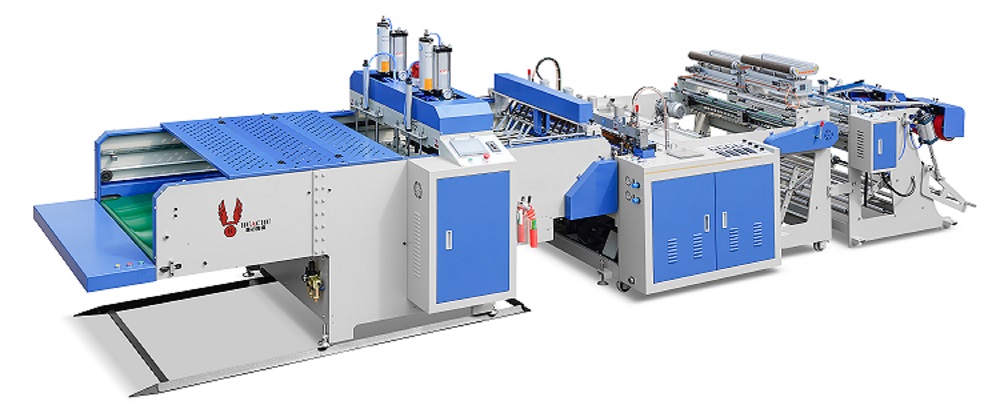

Product Overview

The High Speed 2 Lines T-shirt Bags Making Machine with EPC is a professional-grade bag production device engineered to process various low-density polyethylene (LDPE) and high-density polyethylene (HDPE) blown plastic films. With its dual-line operation design, this machine stands out in the packaging machinery market for its high efficiency and stable performance, making it a top choice for manufacturers engaged in large-scale civil and industrial product packaging. It is widely applicable to package food, fruits, clothing, textiles, daily necessities, and other items, effectively meeting the diverse packaging needs of different industries. What’s more, integrated with the Edge Position Control (EPC) system, it ensures precise film alignment throughout the production process, minimizing material waste and guaranteeing consistent bag quality. Whether for mass production of retail bags or industrial packaging liners, this machine delivers reliable and high-speed performance that exceeds industry standards.

Key Performance & Characteristics

High-efficiency Double-line Production Capacity

This machine is designed for maximum productivity, with a working speed of 220-280 pieces per minute per line, which means it can produce up to 560 bags per minute in total. The dual-line structure enables simultaneous production of two rows of T-shirt bags, doubling the output efficiency compared with single-line equipment. This feature is particularly beneficial for businesses with large-order demands, helping them shorten delivery cycles and improve market competitiveness. In addition, it supports a wide range of bag sizes, with a maximum bag width of 500mm per line and a length range of 350-700mm per line, providing flexibility for producing different specifications of bags to meet diverse customer requirements.

Precision Control System with Brand Components

Equipped with high-quality components from well-known brands, the machine ensures stable and accurate operation. It adopts an Inovance servo motor and a Delta inverter from Taiwan, which realize smooth speed regulation and reduce mechanical wear, thus extending the service life of the equipment. The XC PLC controller and WeinView touch screen from Taiwan enable intuitive and user-friendly operation. Operators can easily set and adjust production parameters such as bag length, sealing temperature, and speed, reducing setup time and operational errors. Moreover, the Panasonic photocell from Japan ensures accurate positioning during the cutting and sealing process, while the Omron temperature controller from Taiwan maintains consistent heat for reliable sealing quality.

Heavy-duty Structure for Continuous Operation

Built with a robust frame, the machine weighs 2500kg and has dimensions of 6000×1840×1800mm, providing a stable foundation for long-term continuous operation. The heavy-duty structure effectively reduces vibration during high-speed production, ensuring uniform bag formation and preventing quality defects. Additionally, the included EPC device continuously monitors and corrects film alignment, avoiding edge deviation and material waste, which is crucial for processing thin films with a thickness of 0.008-0.05mm.

Technical Specifications

Parameter | Details |

Model | HCT-500*2 |

Max Bag Width | 500mm × 2 lines |

Max Bag Length | 350-700mm × 2 lines |

Material Thickness | 0.008-0.05MM |

Machine Speed | 220-280pcs/min × 2 |

Main Motor Power | 1.5KW (Dedong, Shanghai) |

Servo Motor | Inovance |

EPC Device | Included |

PLC Controller | XC |

Touch Screen | WeinView (Taiwan) |

Inverter | Delta (Taiwan) |

Photocell | Panasonic (Japan) |

Temperature Controller | Omron (Taiwan) |

Machine Weight | 2500kg |

Machine Dimension | 6000×1840×1800mm |

Application Scenarios

Food & Fruit Fresh-keeping Packaging

The machine can produce food-grade T-shirt bags suitable for packaging fresh fruits, vegetables, baked goods, and snacks. The precise sealing ensures the freshness of food and extends its shelf life, meeting the hygiene standards of the food industry.

Clothing & Textile Storage Packaging

It is ideal for manufacturing lightweight and durable bags for packaging clothing, textiles, and fabrics. The stable production process ensures that the bags have uniform size and strong load-bearing capacity, preventing damage to the packaged items during transportation and storage.

Daily Necessities & Industrial Product Packing

The machine also caters to the packaging needs of daily necessities such as toiletries and household goods, as well as industrial products like small parts and components. Its high-speed production capacity can meet the large-scale packaging requirements of factories and enterprises.

FAQ

What is the main advantage of the double-line design compared to single-line machines?

The double-line design allows the machine to produce two rows of T-shirt bags at the same time, which doubles the production efficiency. It is especially suitable for manufacturers with large-order volumes, helping them reduce production costs and improve market responsiveness.

How does the EPC device improve production quality?

The EPC device continuously monitors the edge position of the plastic film during the production process. If any deviation is detected, it will automatically adjust the film to ensure accurate alignment. This not only guarantees consistent bag width but also minimizes raw material waste, especially when processing thin films.

Can this machine handle ultra-thin plastic films with a thickness of 0.008mm?

Yes, the machine is designed to process plastic films with a thickness range of 0.008-0.05mm. The precision control system and stable mechanical structure ensure smooth feeding and processing of ultra-thin films without tearing or deformation.

Call to Action

Are you looking for a high-efficiency double-line T-shirt bag making machine to boost your production capacity? Our High Speed 2 Lines T-shirt Bags Making Machine with EPC is the perfect solution for you! It combines high-speed production, precision control, and durable construction to meet all your packaging needs. Contact us now to inquire about pricing, customization options, and technical support. Don’t miss this opportunity to upgrade your packaging production line—Add to Basket today and take your business to the next level!