Introduction

Did you know the blow-up ratio (BUR) can drastically change the quality of your film? This simple yet powerful factor plays a key role in Film Blowing Machines, influencing properties like thickness, strength, and clarity.

In this article, we’ll dive into how the blow-up ratio affects the film quality and what it means for your production process. You’ll learn how to optimize this ratio to achieve the best results for different applications, whether you’re in packaging, agriculture, or industrial sectors.

Understanding the Blow-Up Ratio (BUR)

What is the Blow-Up Ratio?

The blow-up ratio (BUR) refers to the ratio of the diameter of the inflated film bubble to the diameter of the die from which the film is extruded. It directly influences the stretching of the film as it’s produced, which impacts both its physical properties and its performance in real-world applications.

In practical terms, a higher blow-up ratio increases the amount of stretching, resulting in a thinner film. On the other hand, a lower BUR results in a thicker film, which may be more durable but less flexible.

For manufacturers using Film Blowing Machines, understanding the blow-up ratio is key to achieving the right balance between cost-efficiency, performance, and product quality. By adjusting the BUR, businesses can control the properties of the film to meet specific needs, such as creating packaging films that are both flexible and strong or agricultural films that are thick and durable enough to withstand outdoor elements.

How is the Blow-Up Ratio Calculated?

The blow-up ratio is calculated using the following formula:

BUR = (Bubble Diameter) / (Die Diameter)

However, in real-world applications, operators often measure the layflat width (the width of the film when flattened) and use the following formula for calculation:

BUR = (0.637 × Layflat Width) / Die Diameter

For instance, if a film has a layflat width of 600 mm using a 100 mm die, the BUR would be:

BUR = (0.637 × 600) / 100 = 3.82:1

This calculation is crucial in helping operators adjust settings in the Film Blowing Machine to achieve the desired film properties, ensuring consistency across production runs. Accurately calculating the BUR allows operators to optimize the extrusion process for specific materials, minimizing material waste and production downtime.

Optimizing the BUR for a specific material, such as HDPE or LDPE, will result in films that meet the required thickness, strength, and clarity, allowing manufacturers to satisfy customer needs more effectively.

Key Effects of the Blow-Up Ratio on Film Quality

Thickness and Uniformity of the Film

The blow-up ratio has a direct impact on the thickness and uniformity of the film. A high BUR typically results in a thinner film as it causes more stretching during the extrusion process. This can be beneficial for applications that require lightweight, flexible films, such as food packaging or agricultural films. However, too high of a BUR can lead to film thinning, making it more susceptible to tearing and breakage.

For example, in the case of agriculture films, manufacturers may prefer a lower BUR to achieve a thicker, more durable film that can withstand harsh weather conditions. Conversely, in the food packaging industry, a higher BUR is often preferred to ensure the film is thin enough for easy handling and conformability.

A lower BUR results in a thicker film, which is ideal for applications that require stronger, more durable films. However, excessive thickness can affect the flexibility and optical clarity of the film, making it less suitable for certain applications, such as transparent food packaging.

Table 1: Thickness vs. Blow-Up Ratio

Blow-Up Ratio | Film Thickness | Application |

1.5:1 | Thick | Heavy-duty packaging |

2.5:1 | Moderate | Standard packaging |

4.0:1 | Thin | Lightweight films |

Tip: For applications requiring both strength and flexibility, such as food packaging, a moderate blow-up ratio can help balance thickness and clarity. Ensuring optimal film thickness is critical for ensuring a product meets both durability and aesthetic standards.

Mechanical Strength of the Film

The blow-up ratio plays a critical role in determining the mechanical strength of the film. It affects the film’s tensile strength and elongation in both the machine direction (MD) and transverse direction (TD).

● High BUR: A higher blow-up ratio enhances the film’s strength in the transverse direction (TD), which increases its tear resistance and flexibility. This is particularly important for stretch films used in wrapping applications where the film must stretch to fit around objects. Films with higher BUR values are commonly used in industrial applications where stretchability is crucial.

● Low BUR: A lower blow-up ratio increases the strength of the film in the machine direction (MD), making it better suited for vertical strength, which is important for films used in sacks, bags, and other materials that need to resist forces in one direction.

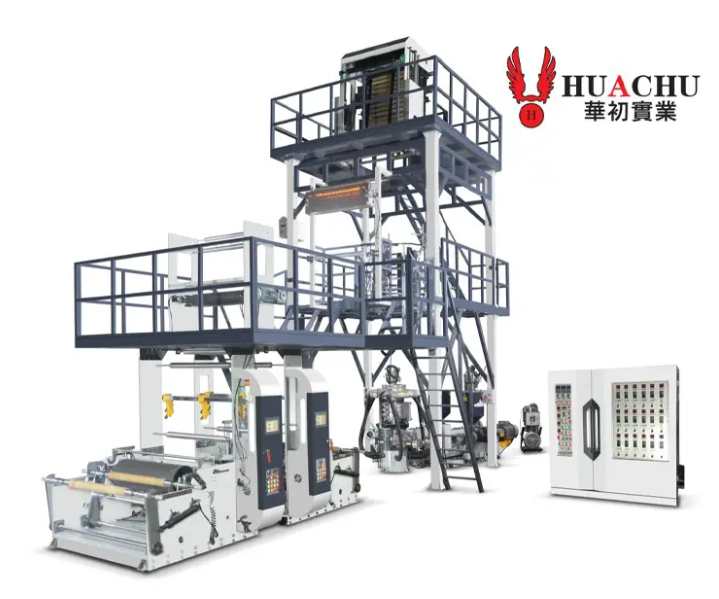

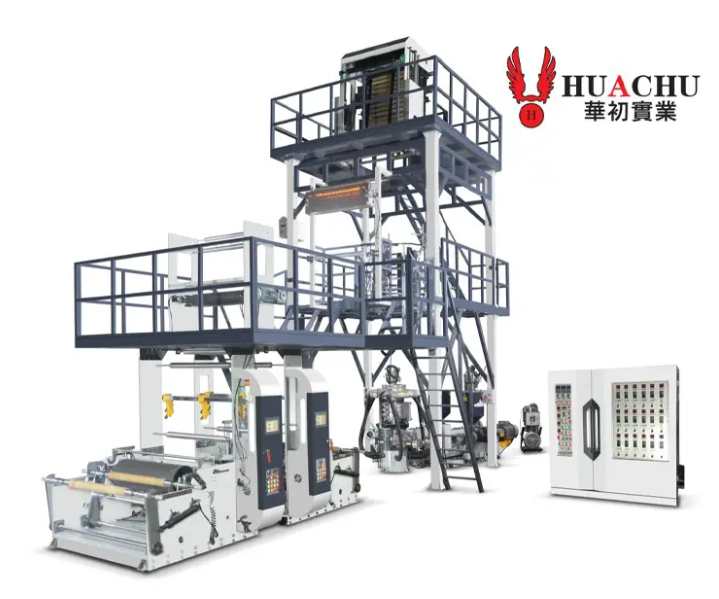

This distinction is crucial when selecting the Film Blowing Machine configuration for different industries. Wenzhou Huachu Machinery Co., Ltd., known for its high-quality HDPE/LDPE/LLDPE blow molding machines, specializes in producing machines capable of adjusting the BUR for optimal tensile strength, ensuring their customers get the most reliable and durable films for their specific applications.

Clarity and Optical Properties

In addition to mechanical properties, the blow-up ratio also affects the optical properties of the film, particularly its clarity and haze. Films with a higher BUR tend to exhibit greater molecular orientation, improving the alignment of molecules, which in turn improves clarity and reduces haze.

However, the increased molecular alignment can also reduce the gloss of the film, which may not be desirable for applications that require a shiny, high-quality appearance, such as food packaging.

On the other hand, films with a lower BUR are generally clearer but may sacrifice some strength and flexibility.

Table 2: BUR vs. Optical Properties

Blow-Up Ratio | Clarity | Haze Level | Gloss Level |

1.5:1 | High | Low | High |

3.0:1 | Moderate | Moderate | Moderate |

5.0:1 | Low | High | Low |

Tip: For clear packaging, prioritize a lower blow-up ratio to achieve the desired optical clarity while still maintaining a balanced performance in terms of strength and flexibility.

Optimizing the Blow-Up Ratio for Desired Film Properties

Balancing BUR for Specific Applications

The key to producing high-quality films lies in optimizing the blow-up ratio based on the intended application. For example:

● Packaging films: A moderate BUR ensures a balance between strength and flexibility. This is crucial for easy handling and durability during transportation.

● Stretch films: A higher BUR value maximizes film stretchability, which is necessary for films that must conform to different shapes during packaging or wrapping.

● Agricultural films: Lower BUR values are preferred for applications like mulch films and greenhouse films, where greater strength and thickness are required to withstand environmental stress.

Material Considerations

The ideal blow-up ratio varies depending on the material used. Different types of polymers require different blow-up ratios to achieve optimal performance:

● LDPE / LLDPE: These polymers typically perform best with a BUR range of 2.0:1 to 3.0:1, providing a good balance between strength, toughness, and clarity.

● HDPE: HDPE requires a higher BUR, typically ranging from 3.5:1 to 5.0:1, to achieve the impact strength and tear resistance that are required for certain packaging applications.

Table 3: Optimal BUR Range by Material

Material | Optimal BUR Range |

LDPE / LLDPE | 2.0:1 - 3.0:1 |

HDPE | 3.5:1 - 5.0:1 |

Shrink Film | 3.0:1 - 4.0:1 |

Tip: Adjust the BUR based on the material type to ensure optimal performance and film quality. Doing so allows manufacturers to meet both cost and quality requirements effectively.

Common Issues with Incorrect Blow-Up Ratio Settings

Weakness and Defects

Incorrect BUR settings can lead to several weaknesses and defects in the final film:

● Tear resistance: A low BUR results in poor tear resistance, especially in the transverse direction. This is problematic for films that must resist stress from multiple directions.

● Thickness variation: A high BUR can result in inconsistent film thickness, leading to weak spots that are more prone to tearing.

Visual and Appearance Problems

Films with an incorrect BUR may also display several surface flaws:

● "Boardy" effect: Films that are too stiff, making them difficult to use in flexible packaging applications.

● Wave interfacial instability: This occurs when the film exhibits wavy patterns due to uneven stretching, reducing its visual appeal and marketability.

Tip: Monitor your production process regularly and adjust settings as necessary to prevent defects and ensure consistent film quality.

Best Practices for Controlling the Blow-Up Ratio

Precise Control Over BUR Settings

To ensure high-quality films, manufacturers must exercise precise control over BUR settings. Some best practices include:

● Die alignment: Ensure the die is properly aligned to avoid inconsistencies in film thickness.

● Temperature profiles: Monitor the temperature across the die to ensure uniform heating and optimal BUR.

● Sensor calibration: Use accurate sensors to measure the melt temperature, ensuring that the film is produced at the correct temperature for the desired film quality.

Monitoring and Adjusting Process Settings

External factors such as air pressure, cooling, and take-up speed all affect the blow-up ratio and, in turn, film quality. Regular adjustments to these factors can help prevent defects:

● Air pressure: Affects film expansion and BUR.

● Cooling: Proper cooling stabilizes the bubble and prevents it from becoming unstable, which can lead to defects.

● Take-up speed: Controls how quickly the film solidifies, ensuring uniform thickness and quality.

Tip: Consistently check all process settings, including temperature, air pressure, and take-up speed to maintain high-quality films throughout production.

Conclusion

The blow-up ratio is a crucial factor in determining film quality during the extrusion process. By understanding and optimizing the BUR, manufacturers can achieve the desired balance between thickness, strength, clarity, and flexibility, leading to high-quality films for various applications.

Key Takeaways:

● A high BUR enhances clarity and strength in the transverse direction but may reduce strength in the machine direction.

● A low BUR offers better machine-direction strength but sacrifices flexibility and clarity.

● Regular monitoring and adjustments of BUR settings are essential for achieving consistent, high-quality film production.

By implementing the best practices outlined in this article and adjusting the BUR according to material type and application needs, manufacturers like Wenzhou Huachu Machinery Co., Ltd. can produce high-performance films that meet the specific requirements of their customers, ensuring long-term success in the competitive film production industry.

FAQ

Q: What is the blow-up ratio (BUR) in a Film Blowing Machine?

A: The blow-up ratio (BUR) is the ratio between the diameter of the inflated film bubble and the diameter of the die. It influences the film’s thickness, strength, and clarity, determining the final properties of the produced film.

Q: How does the blow-up ratio affect film quality?

A: A higher BUR generally results in thinner, stronger, and clearer films, ideal for applications like food packaging. Conversely, a lower BUR can produce thicker films with better machine-direction strength, making it suitable for heavy-duty applications.

Q: Why is it important to optimize the blow-up ratio in Film Blowing Machines?

A: Optimizing the blow-up ratio ensures the right balance of thickness, strength, and clarity for the intended application, leading to higher-quality films and more efficient production.

Q: How can I adjust the blow-up ratio to meet different film application needs?

A: The blow-up ratio should be adjusted based on the material being used and the desired film properties. For example, a higher BUR is ideal for flexible films, while a lower BUR is better for stronger, more durable films.

Q: Can an incorrect blow-up ratio affect the production process?

A: Yes, an incorrect BUR can cause issues like uneven thickness, film tears, or surface defects, leading to lower film quality and potential production delays.