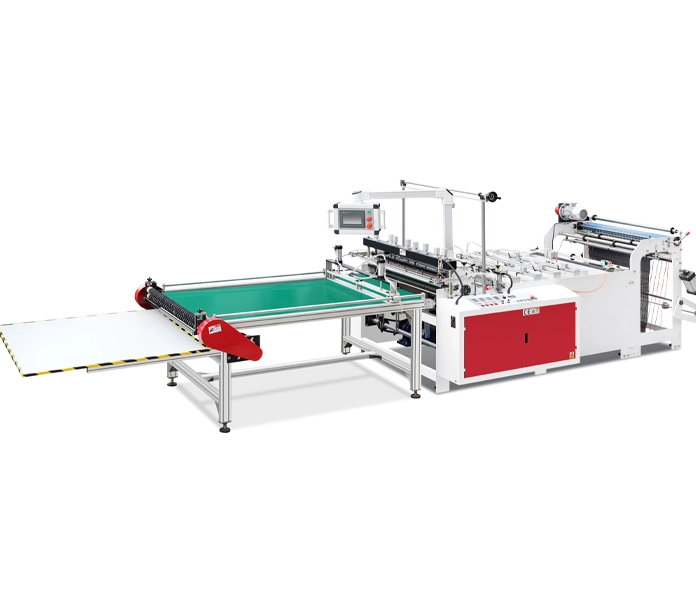

Product Overview

The Side Sealing Bag Making Machine is a high-efficiency and precision-driven device specially engineered for producing plastic bags from PE, PP, and BOPP plastic films. It integrates advanced automation technology and sturdy structural design to meet the packaging needs of various civil and industrial sectors. This machine stands out for its high accuracy, adjustable speed range, and easy operation, making it an ideal choice for businesses aiming to optimize bag production efficiency while ensuring consistent product quality. Whether for small-scale customized bags or large-batch standard packaging bags, this equipment can flexibly adapt to diverse production requirements, effectively reducing operational costs and improving market competitiveness.

Key Performance & Characteristics

Robust & Anti-static Structural Design

The overall frame of the machine is constructed with 10mm-thick steel plates, combined with snap-in assembly and anti-static painting. This design not only enhances the machine’s stability and durability during long-term operation but also prevents static interference with plastic films, ensuring smooth production processes.

Energy-saving & User-friendly Speed Control

It adopts inverter control speed technology, which allows operators to easily adjust the production speed according to bag size and material types. This feature not only simplifies the operation process but also significantly reduces electric consumption, achieving the dual goals of energy saving and cost reduction.

Full-automatic Computer Control System

The machine is equipped with a computer-controlled full-automatic system, paired with a touch screen and human-machine interface. This intelligent setup enables convenient correction and fine adjustment of production parameters, minimizing manual errors and ensuring the cutting and sealing accuracy of each bag.

Dual Hot Sealing Knives for Versatile Materials

It comes with two dedicated hot sealing knives—one for PP films and the other for PE films. This configuration eliminates the need for frequent knife replacement when switching between materials, greatly improving production efficiency and flexibility.

Technical Specifications

Parameter | Value |

Model | HC-SS1000 |

Max. bag width (bag depth) | 990mm |

Min. bag width (bag depth) | 50mm |

Max. bag length | 600mm |

Max speed (pcs/min) | 30-240pcs/min (depend on bag size and material) |

Max sealing thickness | BOPP: 0.012-0.06mm; PP is Ok for every size |

Accuracy | ±0.3mm |

Suitable film | PE, PP, BOPP |

Total power | 5kw |

Weight | 1200kg |

Dimension (LWH) | 4600×1340×2060mm |

Application Scenarios

Food Packaging Industry

The Side Sealing Bag Making Machine can produce food-grade PE and BOPP bags, which are widely used for packaging snacks, dried fruits, and frozen foods. The precise sealing ensures the freshness and hygiene of food products, meeting strict food safety standards.

Fruit & Vegetable Packaging

It is suitable for making breathable and moisture-proof PP bags for fruit and vegetable packaging. These bags can extend the shelf life of produce and facilitate transportation and storage, perfectly fitting the needs of fresh produce suppliers.

Clothing & Textile Packaging

For the clothing and textile industry, the machine can produce customized side-sealing bags with specific sizes to package clothes, fabrics, and textiles. The anti-static design prevents damage to delicate fabrics caused by static electricity during packaging.

Daily Necessities & Industrial Product Packaging

It also caters to the packaging requirements of daily necessities such as toiletries, household chemicals, and industrial products like small hardware and electronic components. The high production speed and stable quality can meet the large-batch packaging demands of these industries.

FAQ

What types of plastic films are compatible with this machine?

This Side Sealing Bag Making Machine is fully compatible with PE, PP, and BOPP plastic films, covering most common plastic packaging materials in the market.

What is the production speed range of the machine?

The maximum production speed ranges from 30 to 240 pieces per minute. The actual speed is determined by the specific size of the bags and the type of raw materials used.

How accurate is the bag cutting and sealing process?

The machine maintains a high accuracy of ±0.3mm, ensuring that each bag has consistent size and tight sealing, without any leakage or deformation issues.

Call to Action

Are you looking for a reliable and high-efficiency Side Sealing Bag Making Machine to upgrade your packaging production line? Our HC-SS1000 model combines robust structure, intelligent control, and versatile material compatibility to meet all your bag-making needs. Don’t hesitate to Inquire about detailed pricing and customization options, or directly Add to Basket to start your efficient production journey!