Introduction

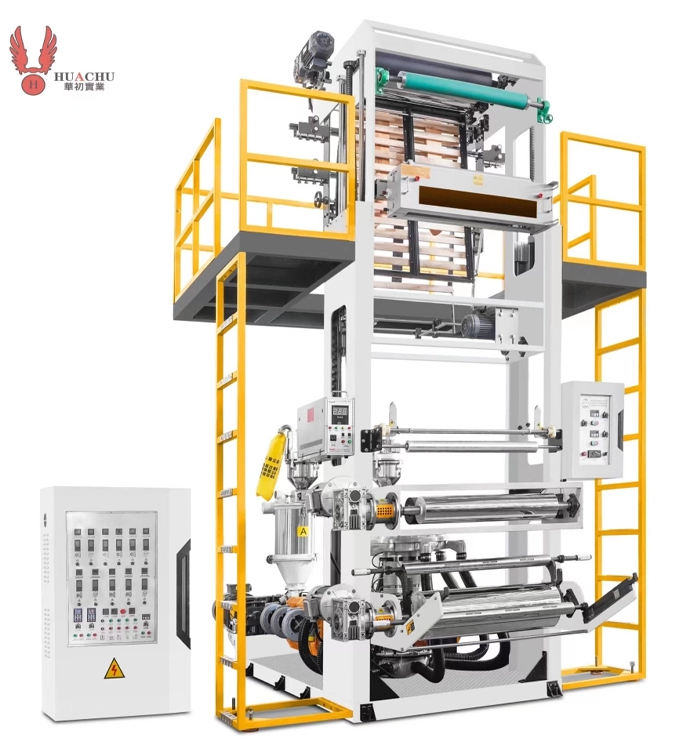

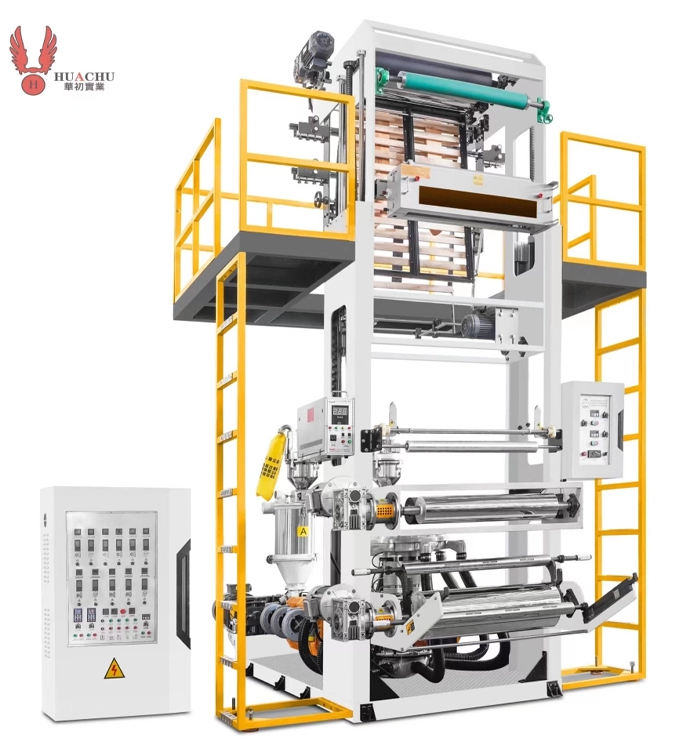

A blown film line can look simple. But one weak part can raise scrap fast. In a Blown Film Extrusion Line, each component affects gauge, stability, and output.

In this article, we break down the key sections of a Blown Film Extrusion Line. You will learn what each part does, what problems it can cause, and what to check for better performance.

Core Components of a Blown Film Extrusion Line

Material feeding and dosing system (hopper, loader, blender)

Feeding controls recipe stability before melting begins. The hopper stores pellets, while the loader keeps it filled. A blender mixes virgin resin, recycle, and additives into one consistent feed. If dosing drifts, output and thickness drift soon. Gravimetric dosing stays steadier than volumetric when bulk density changes.

Extruder system (screw, barrel zones, motor, gearbox)

The extruder melts resin, mixes it, and builds pressure for the die. The screw creates shear heat, while barrel zones shape the melt profile. If zone control drifts, viscosity changes and gauge becomes unstable. Motor and gearbox stability keeps screw speed steady under load. When torque swings, you often see pressure surging downstream.

Melt filtration and pressure stability (screen changer, melt pump)

A screen changer removes gels and contamination from the melt. Cleaner melt reduces black specks, pinholes, and weak spots in film. Filtration also protects die lips from scratches and build-up. A melt pump can smooth output and reduce pulsation from the screw. It works best when screens are managed on a clear schedule.

Die head and die lips (flow distribution, gauge foundation)

The die head forms the melt into a thin tube, ready for inflation. Its flow distribution strongly affects thickness uniformity across the web. If it is uneven, you will chase gauge bands all shift. Die lips must stay clean and smooth for stable flow. Build-up or nicks can cause streaks and melt fracture at higher rates.

Air ring and external cooling package (single/double lip, airflow balance)

The air ring cools the tube from the outside and stabilizes the bubble base. Single-lip rings are common, while double-lip designs offer finer cooling control. Air balance matters more than “more air” during trouble. Dirty channels can create uneven cooling and bubble lean. Dry, stable air supply helps keep the frost line consistent.

Bubble inflation and internal control options (IBC, pressure control, sensors)

Inflation air sets bubble diameter, layflat, and final film width. Stable internal pressure supports stable gauge and fewer wrinkles. Sensors can track diameter and help correct drift during long runs. IBC adds internal cooling by exchanging hot bubble air for cooled air. It often helps thin films and higher speeds when cooling is the limit.

Tip:Follow the process flow when diagnosing, and change only one variable at a time.

Bubble Forming and Stabilizing Section

Bubble cage and stabilizer (prevent flutter and oval bubble)

A bubble cage guides the rising bubble and keeps it centered. It reduces flutter, which can lead to wandering edges and wrinkles. Stabilizers calm oscillation during speed ramps and recipe changes. Misalignment is a common cause of oval bubble. Check the cage position before changing temperature or airflow.

Cooling tower and frost line management (cooling length, ambient impact)

Tower height gives time for cooling and solidification before collapsing. The frost line shows where the film becomes solid and stable. A high frost line can mean soft film and unstable bubble. A low frost line can change orientation and sealing behavior. Seasonal heat and drafts also move the frost line, so settings may need adjustment.

Collapsing frame and alignment guides (flatness, edge tracking)

The collapsing frame turns the bubble into a flat web for hauling and winding. If it is off-center, the web folds unevenly and creates wrinkles. Edge guides help keep the layflat centered over rollers and cores. Poor geometry can trap air and create baggy edges. Small angle changes can make large roll defects.

Haul-off and nip rollers (draw control, tension stability)

Haul-off speed sets draw-down and strongly affects film thickness. Nip rollers seal the bubble top and help stabilize internal pressure. Uneven nip pressure can cause slip, wandering, and chatter marks. Roller wear can also create tension spikes and diagonal wrinkles. Clean, align, and inspect rollers on a fixed routine.

Note:Many “bubble faults” start from cooling imbalance, so verify airflow symmetry early.

Winding and Roll Handling Components

Winder types (surface, center, turret) and when each fits

Winders convert a stable web into sellable rolls. Surface winders are common for general packaging films at moderate speeds. Center winders hold tension more precisely on sensitive films. Turret winders reduce downtime during roll changes at higher output. Your best choice depends on speed, roll diameter, and film slip behavior.

Tension control and lay-on systems (roll hardness, telescoping control)

Tension shapes roll hardness and roll face quality. Too much tension can stretch the web and cause neck-in. Too little tension can trap air and create loose rolls. Lay-on systems help pack the roll more evenly during build. Telescoping often points to poor tension profile or core alignment issues.

Slitting, trimming, and edge management (clean edges for converting)

Trimming removes thick edges and improves converting performance. Clean edges reduce tearing, blocking, and sealing issues later. Dull blades can create fuzz and start edge tears during winding. Thin films need sharp blades and stable wrap angles. If trim waste wraps rollers, tension or waste handling needs correction.

Roll quality checks (wrinkle control, roll density, defect tagging)

Roll checks prevent shipping problems and repeat complaints. Check hardness, edges, roll face, and wrinkle patterns each roll. Repeat wrinkles often point back to collapsing or winding tension. Defect tagging helps trace problems to time, recipe, and station. Simple logs help teams learn faster and reduce repeated scrap.

Winder choice | Best for | Main risk |

Surface winder | General packaging film | Loose rolls at high speed |

Center winder | Precise tension needs | Core slip or telescoping |

Turret winder | Fast changeovers | More tuning and training |

Control, Automation, and Quality Monitoring

PLC/HMI control panel (recipes, alarms, trending)

The PLC and HMI coordinate temperatures, speeds, and alarms across the line. Recipes store repeatable settings for different products and resins. Trending shows slow drift that operators may not notice. Alarms help stop problems before scrap grows. Good recipe discipline reduces shift-to-shift variation.

Temperature and speed synchronization (zone control, screw speed, haul-off speed)

Stable temperature zones prevent gels, degradation, and viscosity swings. Large zone jumps can create unstable melt and gauge drift. Speed sync matters too, since screw speed sets flow and haul-off sets draw. If they move out of sync, thickness shifts quickly. Use smooth ramp rates during start-up and changeovers.

Online thickness and width monitoring (gauge scan, layflat sensors)

Online tools turn film quality into visible data. Gauge scanners show thickness patterns, which can reveal die or cooling imbalance. Layflat sensors track width and support stable bubble control. Sensors need cleaning and calibration to stay reliable. Bad signals can trigger over-correction and create oscillation.

Data logging for traceability (shift reports, lot tracking, preventive actions)

Logging links each roll to resin lot, recipe, and operating conditions. It speeds root cause work after a complaint or defect spike. Shift reports should note screen changes, cleanings, and abnormal events. Over time, the data shows what actions reduce defects. It also supports training and better preventive planning.

Utilities and Supporting Systems That Affect Line Performance

Cooling utilities (chiller, water loop, heat exchanger health)

Cooling utilities support air rings and IBC heat exchangers on many lines. If water temperature drifts, cooling capacity changes and the frost line moves. Fouled heat exchangers reduce heat transfer and waste energy. Watch inlet and outlet temperatures to spot drift early. Clean and maintain the loop on a set interval.

Compressed air system (air ring stability, moisture control)

Compressed air feeds air rings and some control devices. Pressure drops can cause bubble wobble and gauge variation. Moisture can change cooling behavior and leave marks on film. Oil carryover can contaminate the surface and hurt printing. Filters, dryers, and leak checks keep air quality stable.

Resin handling and drying support (when drying matters, contamination prevention)

Many PE resins do not need drying, yet cleanliness always matters. Dust and foreign particles create gels and increase screen loading. Recycled resin often carries fines, moisture, and mixed melt properties. Good storage and sealed transfer reduce contamination risk. Clean hoppers and lines often prevent defects better than larger changes.

Safety systems (interlocks, guards, emergency stops)

Safety systems protect operators and prevent costly damage. Guards reduce risk around rotating shafts, hot zones, and nip points. Interlocks stop motion when guards open, which prevents accidents. Emergency stops must be reachable and tested regularly. Safe threading and lockout habits also reduce unplanned downtime.

Note:When quality shifts suddenly, verify utilities first, then adjust process settings.

Common Blown Film Extrusion Line Configurations by Product Goal

Mono-layer vs multilayer (ABA/ABC) and component changes

Mono-layer lines are simpler and easier to stabilize. Multilayer lines add co-extrusion, so control and dosing matter more. ABA structures often use a cost-saving core layer. They can place recycled resin or CaCO3 in the center layer. That reduces cost while keeping surface quality higher. It also increases filtration needs and screen change frequency.

Rotary die head and oscillating haul-off (why they help gauge uniformity)

Rotary dies help average fixed thickness patterns around the circumference. Oscillating haul-off spreads remaining variation across roll width. These tools work best when defects are repeatable and stable. They do not fix random surging from feeding or pressure. Confirm the pattern type before investing. Then evaluate payback through scrap and complaints reduction.

Wide agricultural films (tower height, cooling demand, winding width control)

Wide agricultural films need stronger cooling and better centering control. Taller towers give more cooling time and improve stability. Air ring symmetry becomes critical as width increases. Winding wide film needs careful tension to avoid baggy edges. Strong web guiding can reduce edge wander. Roll handling also needs space and safer lifting methods.

Recycled resin and CaCO₃ use cases (feeding, filtration, stability needs)

Recycled resin lowers cost, yet it adds variability and contamination risk. CaCO3 changes viscosity and can raise filter loading. Both materials can increase pressure swings and gauge drift. Stable blending and consistent dosing reduce much of the variation. Strong filtration and clear screen routines protect the die. Core-layer placement often protects optics and printability.

How to Evaluate and Maintain a Blown Film Extrusion Line

Buyer checklist by component (what to ask suppliers, what to inspect)

Ask suppliers about gauge stability, bubble stability, and recipe features. Confirm service response, spares availability, and training support. Inspect access for die cleaning and air ring maintenance. Review screen changer safety and change time. If you plan recycled resin, ask about filtration upgrades. A clear checklist prevents expensive surprises after installation.

Commissioning and acceptance tests (output, gauge tolerance, stability targets)

Commissioning should test real products under real run conditions. Set targets for output, gauge tolerance, and roll quality before testing. Run long enough to see drift, not only a short sample. Packaging films need seal and haze checks. Agricultural films need thickness uniformity and tear checks. Log conditions to support training after handover.

Preventive maintenance plan by section (filters, die cleaning, air ring checks)

Preventive work keeps control stable and reduces emergency stops. Plan screen checks by hours and by pressure trend limits. Plan die cleaning by resin type and output level. Clean air ring channels and verify balance on a routine schedule. Inspect rollers, bearings, and winder alignment regularly. Calibrate sensors on a fixed cycle to avoid false control signals.

Fast troubleshooting map (symptom → likely component → quick verification steps)

Fast troubleshooting needs a simple, shared map for operators. Start by naming the symptom and its start time. Then check the most likely station before changing many settings. Verify one cause at a time using quick measurements. The table below offers a practical starting point. Update it using your own logs and product history.

Symptom | Likely station | Quick verification |

Repeat gauge bands | Die lips or distribution | Check die profile, check rotation |

Random gauge surging | Feeding or melt pressure | Check feeder, check pressure trend |

Bubble breathing | Air ring or internal control | Check air balance, check sensors |

Wrinkles on roll | Collapsing or winding | Check alignment, check tension |

Black specks | Resin or filtration | Inspect resin, inspect screens |

Tip:Keep one “golden recipe” per product to restore stability after trials.

Conclusion

A blown film extrusion line consists of several components working in harmony. Each part plays a vital role in ensuring stable production and high-quality film output. By understanding the core components and addressing potential issues, you can significantly improve performance, reduce defects, and enhance operational efficiency.

Wenzhou Huachu Machinery Co., Ltd. offers advanced Blown Film Extrusion Line solutions that focus on precision, reliability, and quality control. Their equipment helps manufacturers optimize production and meet the ever-growing demands of the film industry.

FAQ

Q: What is a Blown Film Extrusion Line?

A: A Blown Film Extrusion Line is a setup that uses an extruder, die, and cooling system to produce plastic films. It is essential for creating various plastic products used in packaging, agriculture, and industrial applications.

Q: How does the IBC system improve a Blown Film Extrusion Line?

A: The IBC system (Internal Bubble Cooling) optimizes cooling during the film production process. It helps maintain bubble stability and prevents film thickness variations, leading to higher-quality films with consistent properties.

Q: What are common issues in Blown Film Extrusion?

A: Common issues include bubble instability, uneven film thickness, wrinkles, and poor film clarity. These can be addressed by adjusting process parameters, ensuring proper cooling, and maintaining equipment.

Q: How can I prevent film sticking at the film mouth of the Blown Film Machine?

A: To prevent film sticking, ensure proper cooling and adjust the resin feed rate. Regularly clean the die and check for any build-up that could cause sticking during the extrusion process.

Q: What maintenance is required for a Blown Film Extrusion Line?

A: Regular maintenance includes cleaning the die, inspecting the extruder screw, checking temperature zones, and ensuring the air ring is functioning correctly. Preventive care ensures optimal performance and longer equipment life.